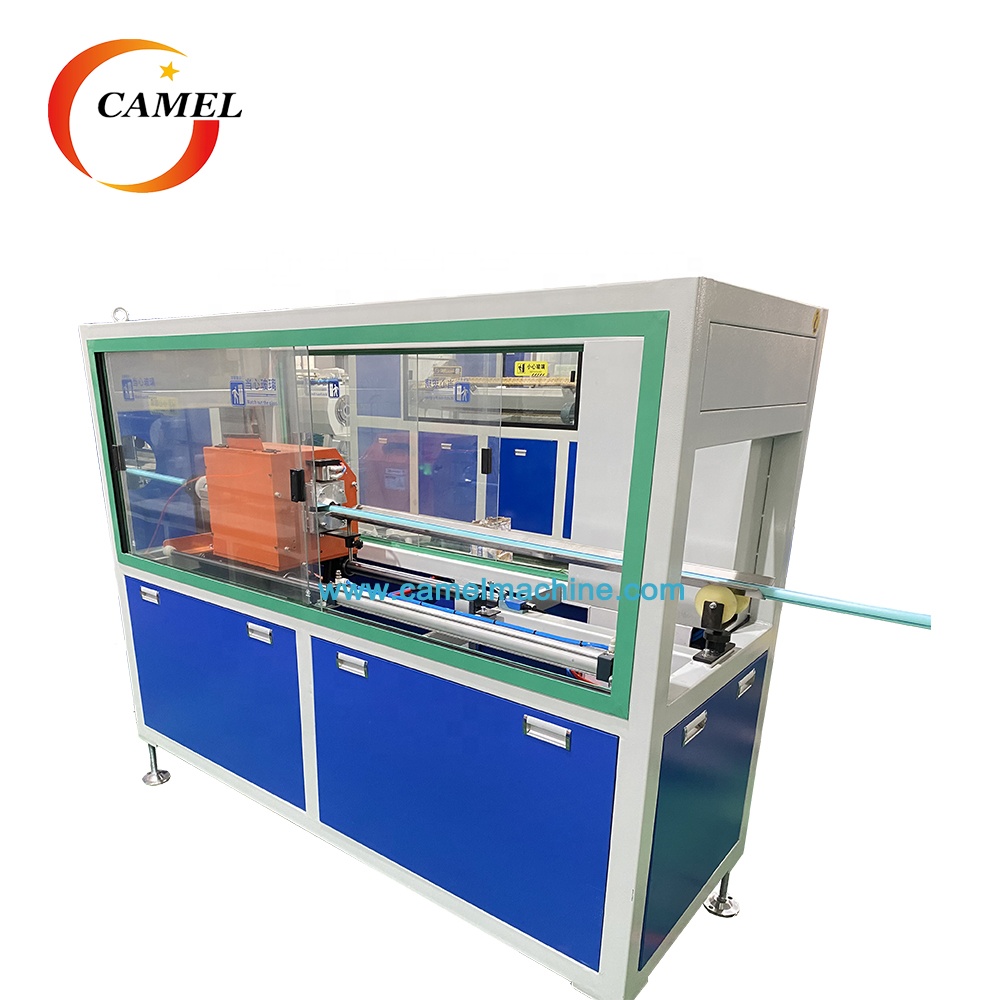

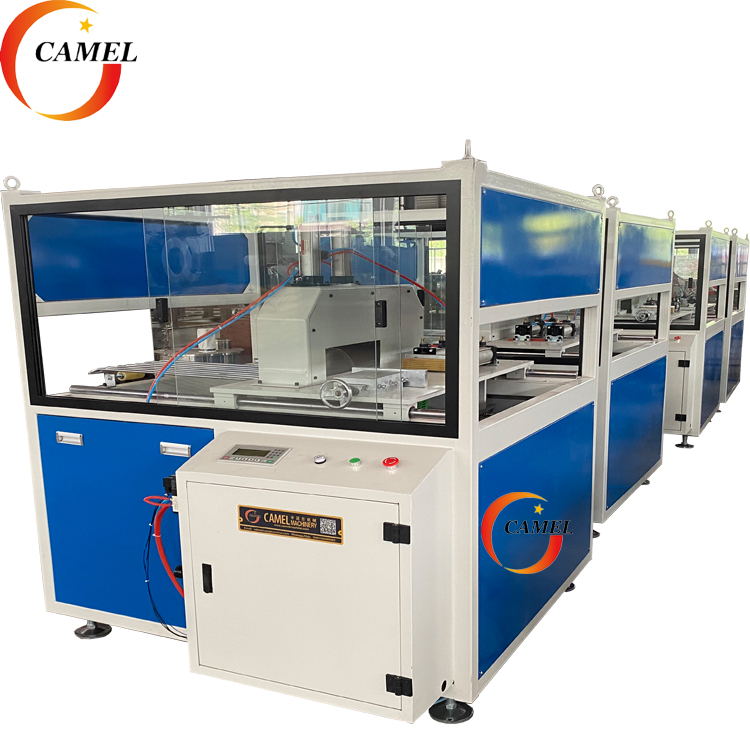

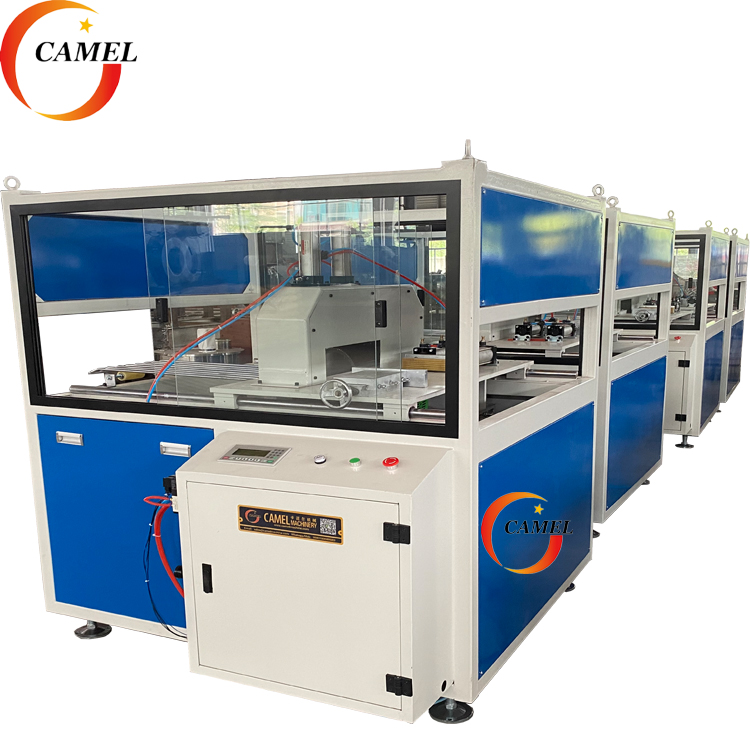

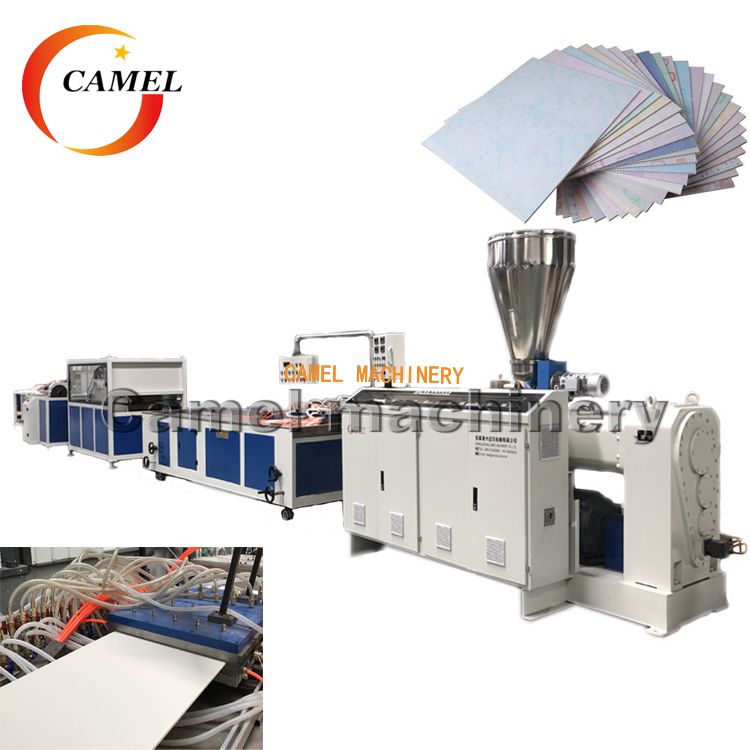

High Speed HDPE Pipe Extrusion/production Machine

High-Performance HDPE Pipe Production Solution Our fully automated HDPE pipe making machine combines advanced engineering with smart technology to deliver exceptional production efficiency and consistent product quality. Designed for maximum reliability and cost-effectiveness, this system is the ideal choice for manufacturers seeking to expand their production capabilities in the plastic pipe industry.