- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

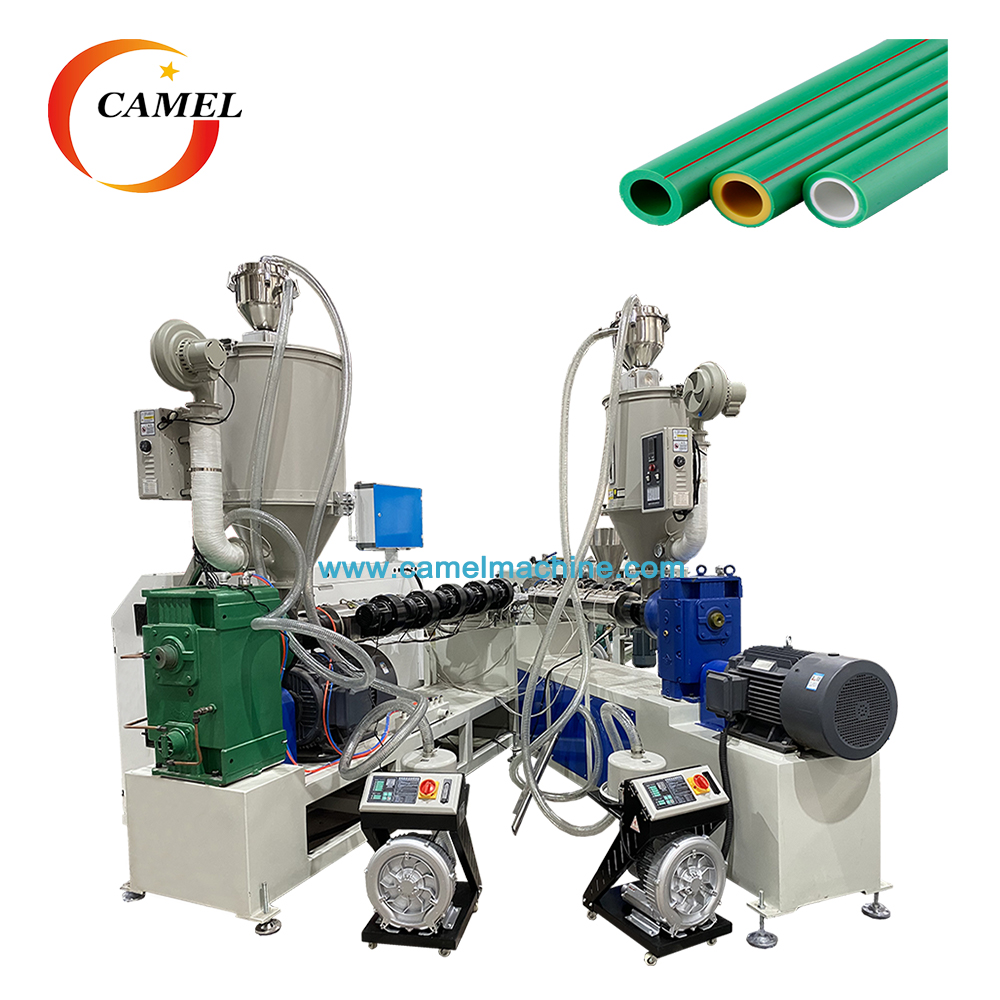

1. Equipped with polyolefin purposed single-screw extruder; it has the characters of quick plasticizing, high efficiency and so on. 2. The specially designed co-extrusion die head is reasonable in flow channel, smooth in both internal and external walls, and small in internal stress. 3. Pipe diameter is among 16-160mm and production speed reaches to 20m/min. 4. One unit serves several purposes. It can be used to produce single-layer common PP-R/PE/PP/HDPE LDPE/PE-RT pipe. 5. If added one co-extruder and die on original base, it can produce multi-layer HDPE pipe, PP-R fiberglass reinforced composite pipe and nano anti-bacteria pipe.

Multi-layer HDPE/PPR Pipe Production Line

Features of hdpe ppr pipe extrusion machine

Features of hdpe ppr pipe extrusion machine

1. Equipped with polyolefin purposed single-screw extruder; it has the characters of quick plasticizing, high efficiency and so on.

2. The specially designed co-extrusion die head is reasonable in flow channel, smooth in both internal and external walls, and small in internal stress.

3. Pipe diameter is among 16-160mm and production speed reaches to 20m/min.

4. One unit serves several purposes. It can be used to produce single-layer common PP-R/PE/PP/HDPE LDPE/PE-RT pipe.

5. If added one co-extruder and die on original base, it can produce multi-layer HDPE pipe, PP-R fiberglass reinforced composite pipe and nano anti-bacteria pipe.

Technical data of ppr pert hdpe pipe making machine

| Model | Screw diameter | L/D |

Extruder Qty (set) |

Pipe range (mm) |

Capacity (kg/h) |

Main power (kw) |

Line length (m) |

| PPR pipe 16-63mm | 65mm | 28:1 or 30:1 | 1 | 16-63 | 100-150 | 55 | 28 |

| PPR pipe 63-160mm | 65mm or 75mm | 28:1 or 30:1 | 1 | 63-160 | 120-180 | 75/90 | 40 |

| PPR glass fiber pipe 20-63mm | 65mm+ 50mm or 65mm | 28:1 or 30:1 | 2 or 3 | 20-63 | 120-220 | 110 | 35 |

Final product of plastic PPR HDPE pipe machine

Multi-layer &single-layer PPR pipe making machine

PPR composite pipe

Single-layer/Multi-layer PE HDPE pipe

Processing line of ppr hdpe pipe production line

extruder → color Line extruder → co-extrusion mould → calibrator → spray vacuum calibration tank → spray cooling water tank → word printer → haul-off → no-dust cutter → pipe rack→final product

1. SJ Serial Plastic Extruder

Extruder model: SJ50/SJ65/SJ75

Main motor power(kw): 55/75/90/110

PLC control: Siemens

Drive motor: Siemens Beide/WEG

Inverter: ABB/delta

Temperature control: Omron

2. Extrusion Mould

2. Extrusion Mould

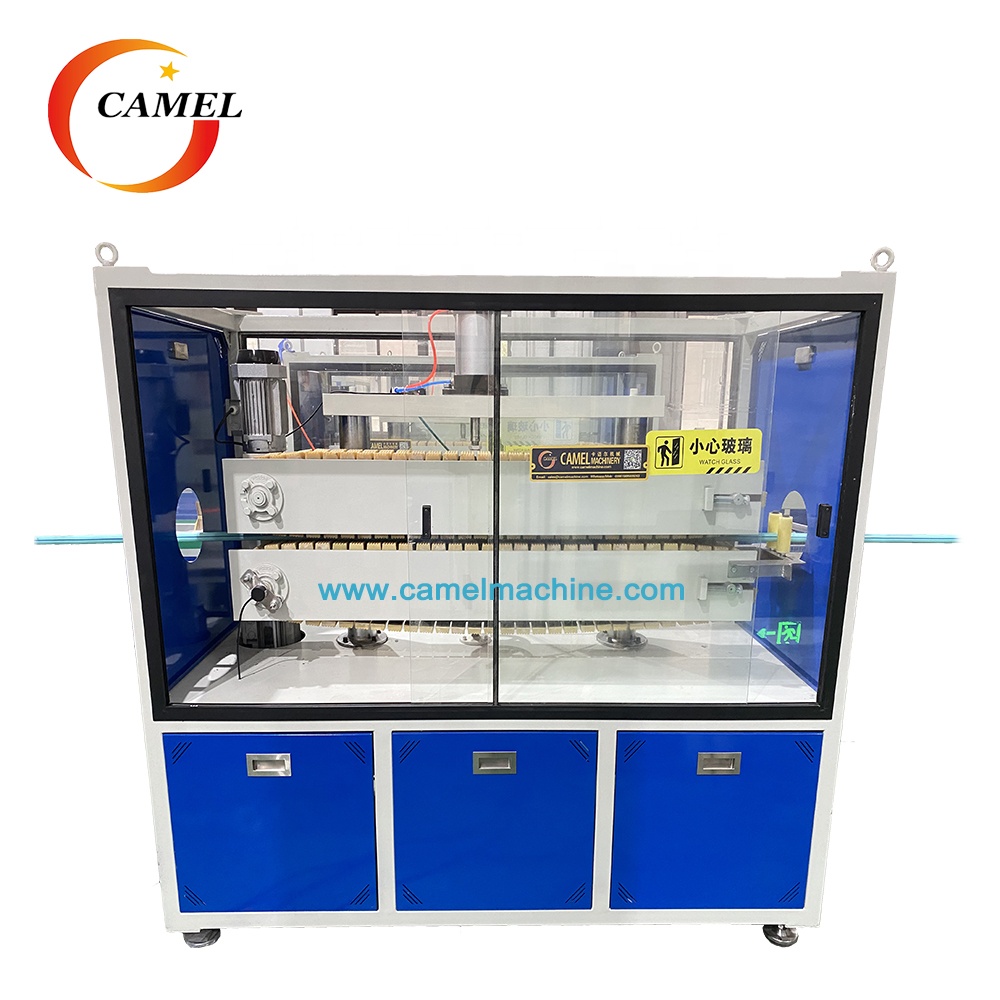

4. Water Spraying Cooling Tank

4. Water Spraying Cooling Tank

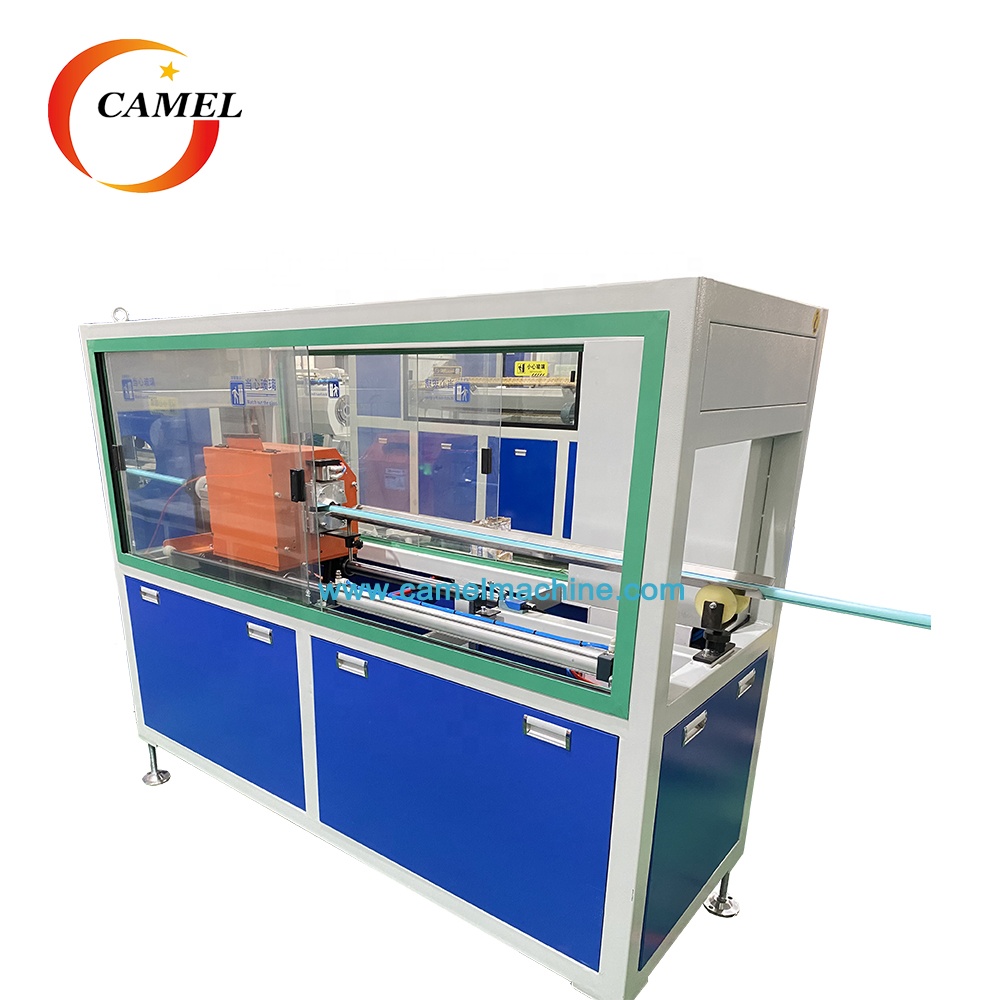

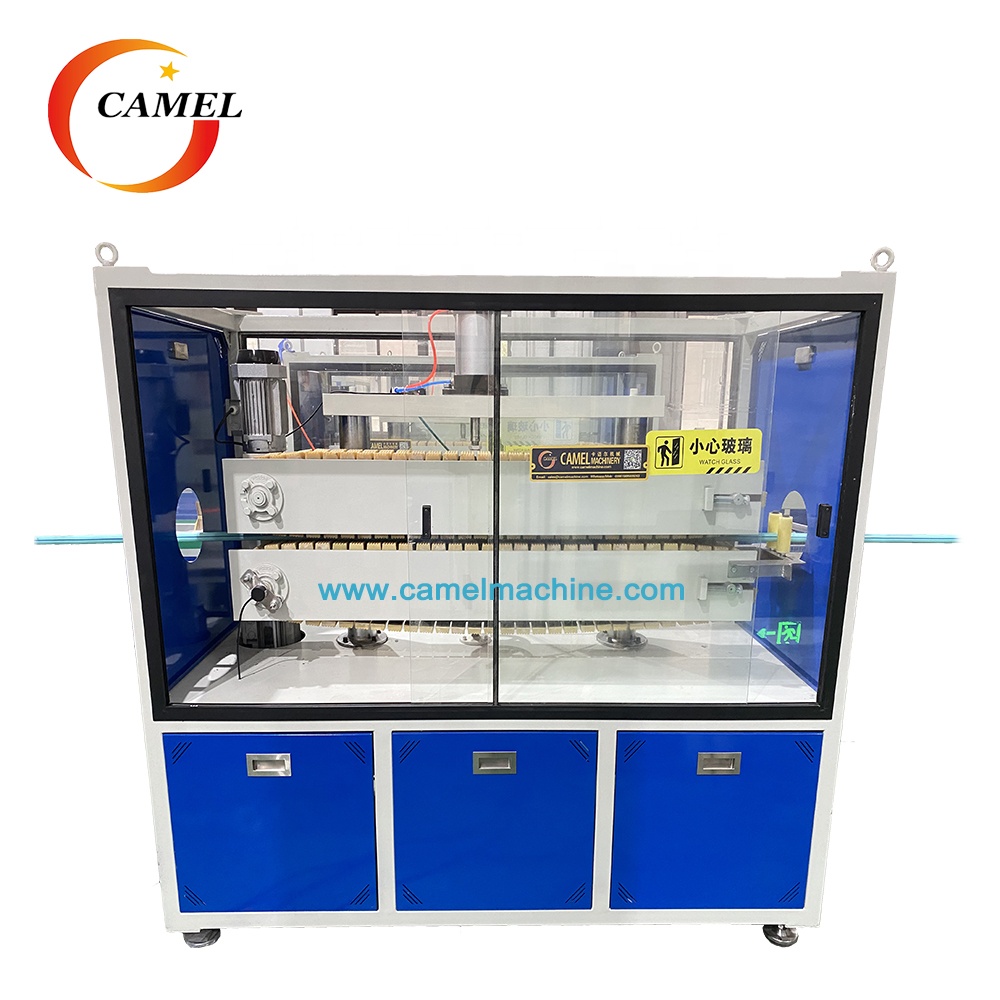

6. Cutting Machine

6. Cutting Machine

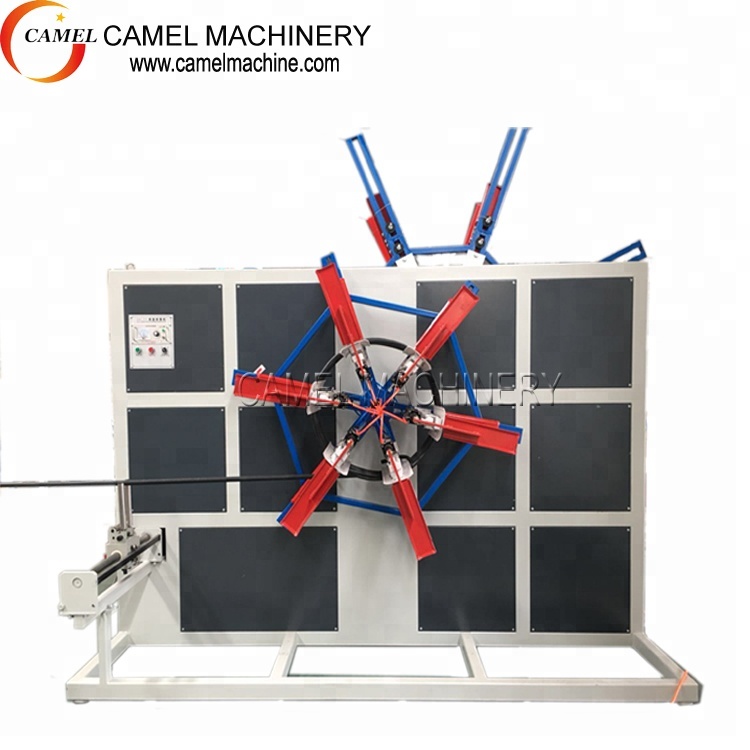

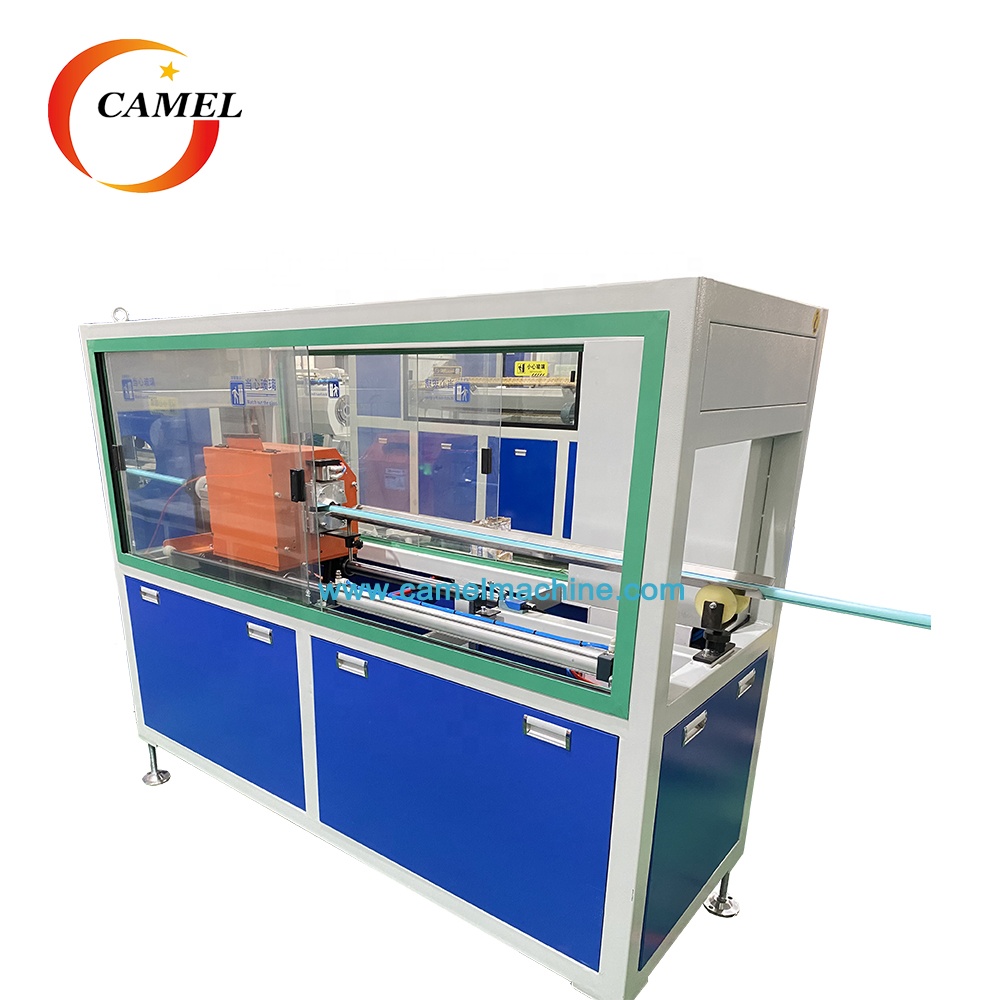

7. Stacker

7. Stacker

Double disc winder for PE HDPE pipe, diameter less than 110mm.

One small disc for 16-63mm

Another big disc for 63-110mm