- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

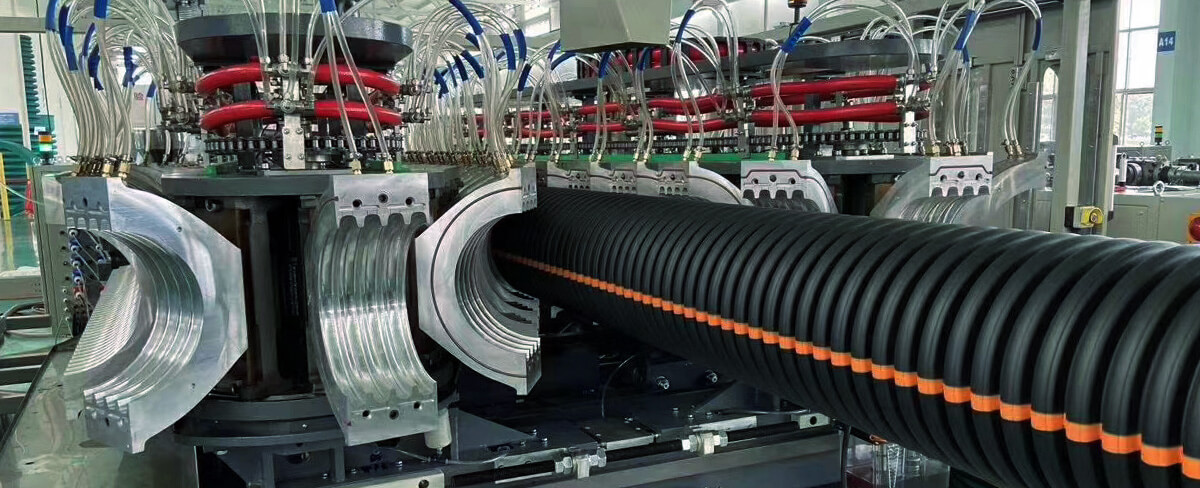

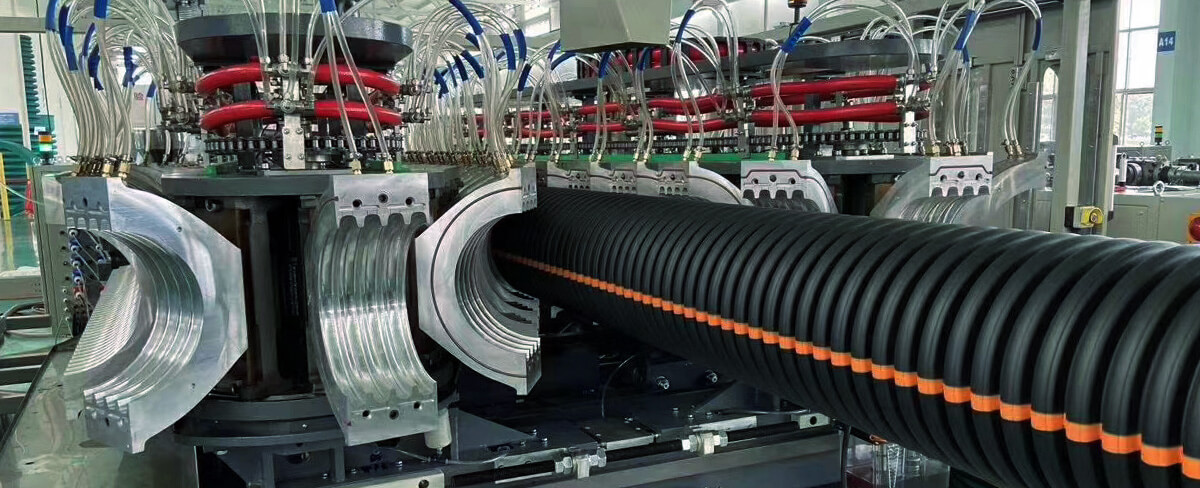

Double wall corrugated pipe is mature product which has the advantage of low weight, low cost, anti-corrosion, good ring stiffness and flexibility. Our company has developed PE double wall corrugated pipe extrusion line for more than 20 years. We have the whole series of double wall corrugated pipe machine: horizontal type, vertical type and shuttle type. Our machine can process wide range of material, including HDPE, PP, PVC, etc.

Our double wall corrugated pipe extrusion line can produce from inner diameter of 63mm to 800mm.

Machine type: normal speed line and high speed line

Structure of forming machine: Horizontal and vertical type

forming mould

hdpe-double-wall

high speed line

cutting machine

forming machine

mould

High speed line

Boot screen

Double wall bellows

Double wall corrugated pipe is mature product which has the advantage of low weight, low cost, anti-corrosion, good ring stiffness and flexibility. Our company has developed PE double wall corrugated pipe extrusion line for more than 20 years.

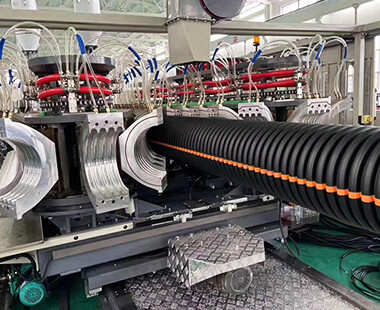

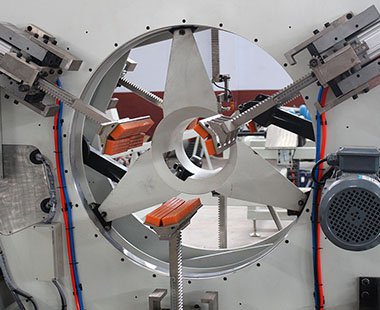

Forming machine and Forming Mould.

1 Siemens Touch Screen and PLC

2 Upper Adjustment System

3 Frame Adjustment System

4 Tension Adjusting System

5 Automatic Lubrication System

6 Proportional Valve

7 UPS Backup Power

8 Mould Cooling System

9 Transmission Gear Rack

10 Mould tooling

Corrugated pipe machine

1 Extremely strong resistance to chemical corrosion and erosion

2 Good flexibility and strong impact resistance

3 Cold resistance and aging resistance. The connection is simple, safe and reliable

4 Light weight and convenient construction

5 Strong wear resistance. The service life is more than 50 years, and it is maintenance-free during the service life

6 Superior drainage performance. It is hygienic and can be recycled and used

| Model | Structure | Raw material | ID (Min.mm) | ID (Max.mm) | Speed (m/min) |

|---|---|---|---|---|---|

| SGB250 | Horizontal | HDPE/pp | 110 | 250 | 0.5-5.0 |

| SGB250 | Horizontal | HDPE/pp | 200 | 500 | 0.5-5.0 |

| SGB600 | Horizontal Nertical | HDPE/pp | 200 | 500 | 0.5-5.0 |

| SGB800 | Vertical | HDPE/pp | 200 | 50 | 0.5-5.0 |

| SGB800 | Shuttle | HDPE/pp | 200 | 500 | 0.5-5.0 |