- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

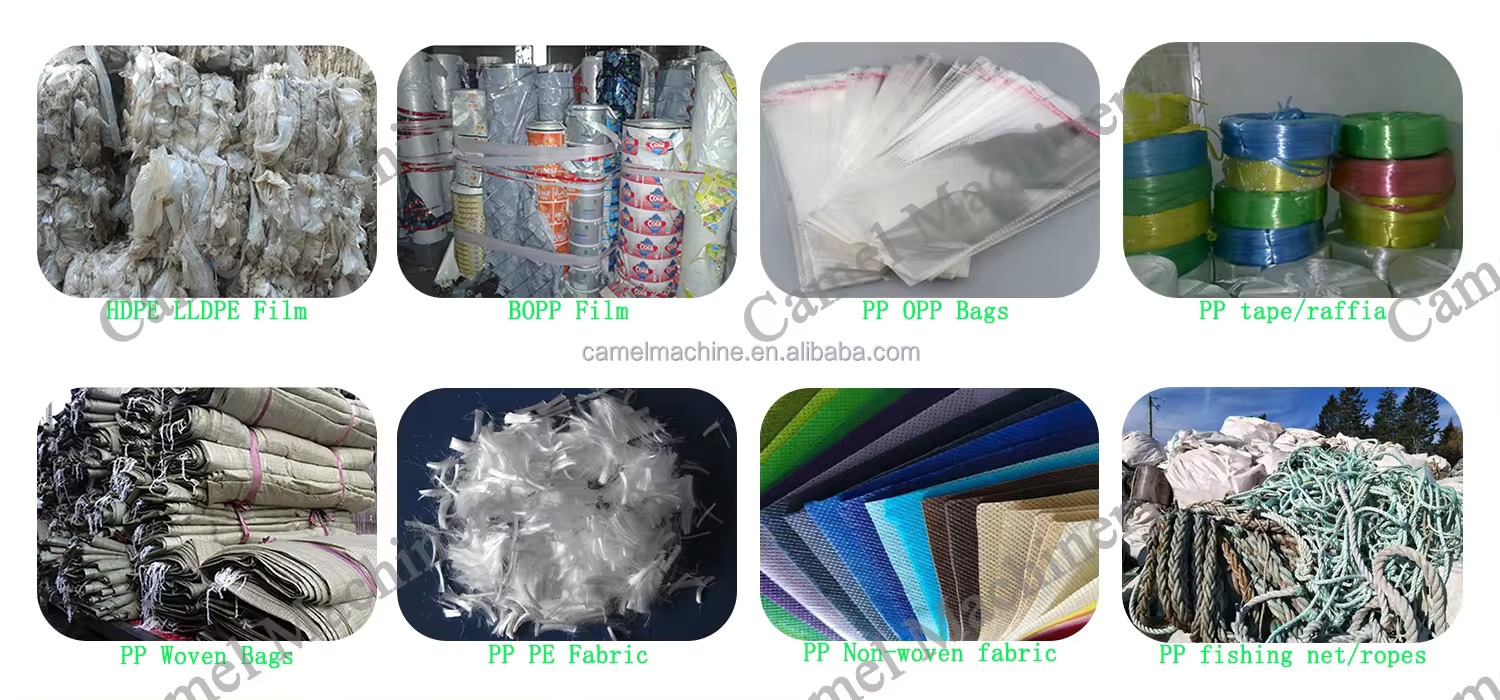

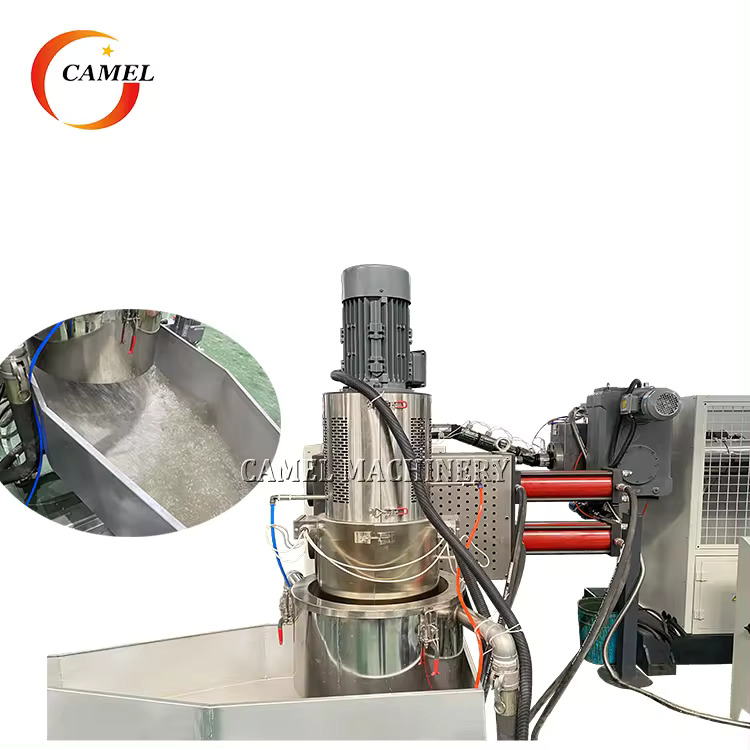

Compacting Water Ring Plastic Pelleting recycling system, which is designed for low density plastic articles. It could provide the excellent re-pelletizing and recycling solution for plastic film, raffia, filament, woven bag, non-woven fabric and some rigid plastic. With compacting cutter to heat and compact the film, it is more easy to feeding material to extruder. Degassing vacuum vent could remove humidity and useless element efficiently. Die face water ring cutting pelletizing system to cut the granules in uniform. The final pellets can be used for film blowing, pipe extrusion and other product injection.

With compacting cutter to heat and compact the film, it is more easy to feeding material to extruder. Degassing vacuum vent could remove humidity and useless element efficiently. Die face water ring cutting pelletizing system to cut the granules in uniform. The final pellets can be used for film blowing, pipe extrusion and other product injection.

| PP/PE Film Compactor Pelletizing Machine | |||||

|---|---|---|---|---|---|

| Model | CL-85 | CL-100 | CL-130 | CL-160 | CL -180 |

| Screw Dia. (mm) | 85 | 100 | 130 | 160 | 180 |

| Screw Dia. (mm) | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

| Output (kg/hr) | 100-200 | 200-300 | 300-400 | 400-500 | 500-600 |

| Double-stage PE PP film pelletizing machine (with agglomerator) | |||||

|---|---|---|---|---|---|

| Model | CL-85/85 | CL-100/100 | CL-130/130 | CL -160/160 | CL -180/180 |

| Screw Dia. (mm) | 85 | 100 | 130 | 160 | 180 |

| L/D Ratio | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

| Output (kg/hr) | 100-200 | 200-300 | 300-400 | 400-500 | 500-600 |

Belt conveyor with metal detector

--Conveyor Belt as standard feeding device for plastic film, raffia, filament, woven bag, non-woven fabric, etc.

--Material of screw adopts qualified nitrided steel(38CrMoAl), process of CNC, with nitride treatment, has the ability of corrosion resistance and wear-resisting.

--Famous brand gear box and motor, high quality heater and cooling fan.

--The rotation of screw push forwar plastic material, to finish the processing of compacting, melting, homogenization.

--With the specialized design of screw, even running with high speed.

--High efficiency and low noise, Long use life and low maintenance cost.

---It is a kind of plastic screen changer or filter which does not need to install a filter, a rough filtering equipment.

---Automatic impurity removal, reduce the labor intensity of workers, reduce the use cost, improve the production efficiency,

---Avoid the shortingcomings of high consumption and high cost of traditional filter screen, sencondary pollution caused by buring wire mesh after use.

---It has the advantages of a high degree of automation and large-volume production, which can increase the recycling rate of recycled materials, and the slag discharge rate.

Hydraulic screen changer

---Adopting dual station filtering channels to work alternately, the screen can be changed quickly without stopping the machine, making it easy for production and maintenance.

---An automatic adjustment sealing device, is good performance and can meet the production of any polymer with high extrusion volume.

---High wear resistance, high pressure resistance, and high-precision filter design improve the effective area and filtration quality.

---Fully filter out invisible impurities in the material to improve the quality of pellets.

Water ring cutter/pelletizer

---The water ring pelletizer adopts the die surface hot cutting system, which not only ensures the smooth and beautiful appearance of the granules, but also enters the cooling water ring in time after the pellets are cut out. -

--Flexible design for die head and cutter knife, which can replace the cutter knife within 2 ~ 3 minutes, with high production efficiency and good stability.

---Cutting speed of pelletizer controlled automatically by PLC according to the pressure of die head, which could achieve the uniform size for output pellets.

---Lower Energy Consumption. Easier Startup.

Dewatering machine and vibrating sieve

---Continuous working and increasing precision of sieving.

---Fully enclosed structure avoids dust overflow, reaching the request of sanitation.

Blower and Storage hopper

---Strong and safe electrical cabinet

---Inverter: ABB/Delta brand

---Contactor/relay: Schneider/Siemens

---PLC control: Siemens

---European standard electrical components.