- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

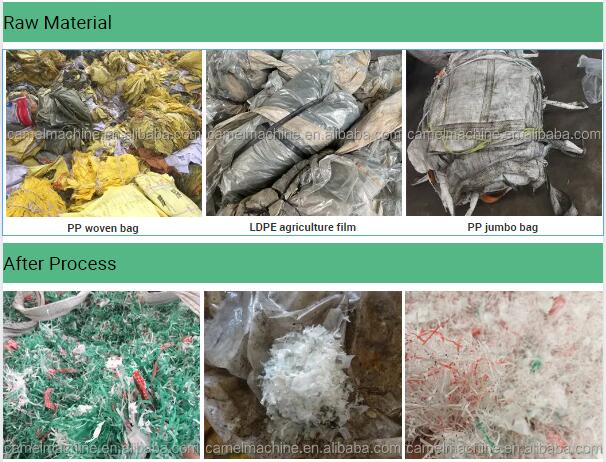

PP Woven Bag Plastic Bottle Recycling Machine Washing Line is a complete recycling line for crushing washing and drying of PP woven bags,PP jumbo bags,PP big bags,PP sacks,PP waste cement bags, etc. Washing and cleaning of PP bag is different from washing of PE film. PP Woven Bags Washing Line is designed with high output, energy saving,stable running features.

PP Woven Bag Recycling Washing Line

PP Woven Bag Washing Line is a complete recycling line for crushing washing and drying of PP woven bags,PP jumbo bags,PP big bags,PP sacks,PP waste cement bags, etc. Washing and cleaning of PP bag is different from washing of PE film. PP Woven Bags Washing Line is designed with high output, energy saving,stable running features.

Features

* Plastic ton bag washing, recycling machine with high output and excellent clean ability.

* Whole plastic recycling line is used to crushing, washing, dewatering and drying the PP ton bag,PP woven bag.

* Simple structure, easy operation, large capacity, energy-saving, safety.

Technical parameter

| Capacity | 300-2000 kg/h |

| Application | food packaging film, agriculture film, green house using film used in oil field, PP bag, PE film, woven bag, LDPE shrink film or heavy printed film, cement bag, oily bag, dirty bag. |

| Specification | Plastic Crusher, High Speed Friction Washer, Centrifugal Dewatering Washer, Screw Feeder, Floating Tank,Screw Feeder.Easily operated with power saving. |

| Output Type | crushing, washing, dewatering, drying,granulating and packaging.The humidity of final output could be within 3% to 5%.Material will be processed by crushing, washing, dewatering, squeezing & aggregating. The humidity of final output could be within 2%. |

| After-sales Service | After-sales Service |

Detail image

PC Series Crusher

The PC series Crusher is to cut the big bag into small flakes by rotating blades inside. The specially design powerful crusher can be provide strong cutting ability. The screen hole inside of the chamber will control the size of PP flakes between 40mm-60mm.

Belt Conveyor

Metal detector for selection.

Floating Washer

The sediment and metal in the material can be effectively separated through this module so as to protect environment from polluting.

Material: stainless steel.

Sediment Removal Machine

The sediment removal machine can wash away the soil and impurities on the surface, while destroying the water vapor layer covering the ton bag, facilitating dehydration, and playing an efficient role in sand washing and cleaning, improving quality.

Screw Feeder

The screw feeder doses the bulk material to the larger diameter extension conveyor. When the bulk material reaches the extension conveyor, the channel load decreases and the bulk material is conveyed to discharge.

Pipe Drying System

This machine is mainly used to use hot air to remove the moisture from PP ton bag scraps.The moisture content after final drying is less than 5%.