- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

WPC Great Wall Panel Machine /outdoor wall cladding panels machine WPC outdoor wall cladding panels machine can produce different kinds of profile. Main material is PE/PP/ABS + wood fiber + other chemical additives composite produce. Product included Wall cladding, Facility of outside park, Handrail, Fence, Decking etc.

WPC Great Wall Panel Machine /outdoor wall cladding panels machine

what is wpc

WPC is the mix of recycled natural fiber (wood powder) and reused plastic materials (HDPE). It’s a new material that recyclable and eco-friendly, and it’s proved an ideal replacement for wood in construction industry. The new material keeps the properties of plastic and texture of wood, making it a perfect combination that features advantages of both plastic& wood materials.

Feature of wood plastic composite products:

1. Natural wood texture

2. 25-30 years long life time, anti-impact, weather- proof, with high density

3. Anti-UV, color stability

5. Easy to be installed and low labor cost

6. Required no painting, no glue, low maintenance

7. 100% recycled, environmental friendly, saving forest resources

8. Barefoot friendly, anti-slip, no cracking

9. Weather resistant, suitable from -30°C to 60°C

Advantages of WPC (Wood Plastic Composite)

1. Looks and feels like natural wood but less timber problems;

2. 100% recycle, eco-friendly, saving forest resources;

3. Moisture/Water resistant, less rotten, proven under salt water condition;

4. Barefoot friendly, anti-slip, less cracking, less warping;

5. Requires no painting, no glue, low maintenance;

6. Weather resistant, suitable from minus 40 to 60°c;

7. Easy to install and clean, low labor cost.

WPC Wall Cladding

WPC Composite outdoor wall cladding is made of 30% HDPE (Grade A recycled HDPE), 60% Wood or Bamboo powder(Professionally treated dry bamboo or wood fiber), 10% Chemical Additives (Anti-UV agent, Antioxidant, Stabilizes, Colorants, Lubricant etc.)

WPC composite wall panel not only has real wood texture, but also has longer service life than real wood and requires little maintenance. So, WPC composite wall cladding is a good alternative of other wall decoration.

WPC (abbreviation: wood plastic composite)

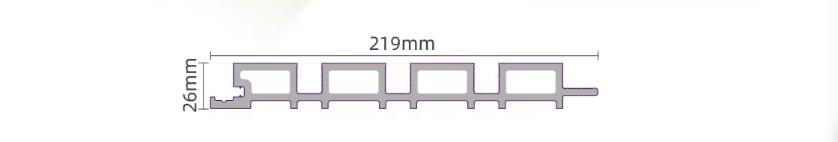

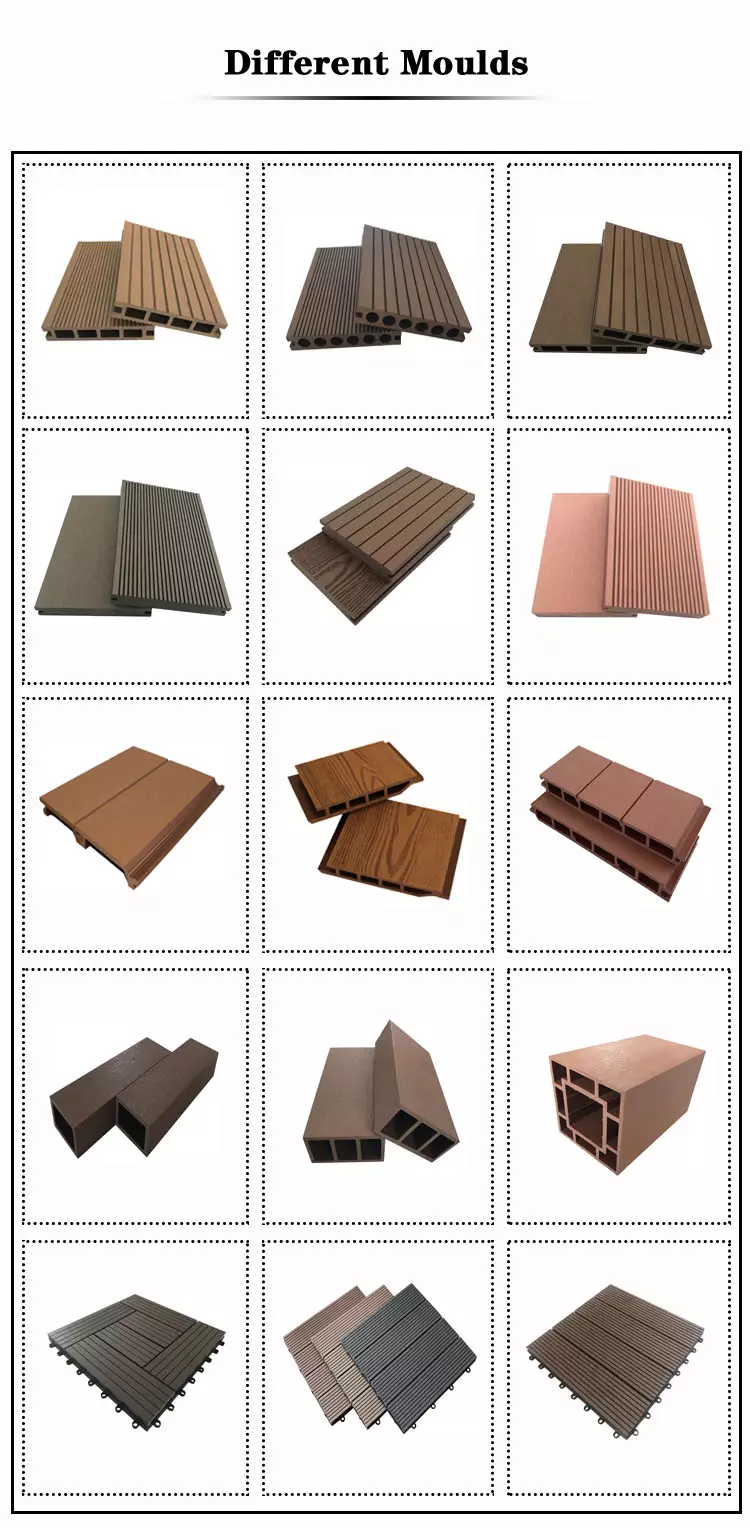

Can also be customized according to customer's drawings and samples.

Product images of plastic wpc great wall panel machine

Technical parameter of outdoor wall cladding panels machine

| Model |

Max width

(mm)

|

Extruder model |

Max output

(kg/h)

|

Motor power

(kw)

|

| CMDX108 | 108 | SJZ51/105 | 100 | 18.5 |

| CMDX108 | 180 | SJZ51/105 or SJZ55/110 | 100/150 | 18.5/22 |

| CMDX 240 | 240 | SJZ65/132 | 250 | 37 |

| CMDX 300 | 300 | SJZ65/132 | 250 | 37 |

| CMDX 400 | 400 | SJZ80/156 | 350 | 55 |

| CMDX 500 | 500 | SJZ80/156 | 350 | 55 |

| CMDX600 | 600 | SJZ80/156 | 400 | 75 |

Technical profile for industry

1.Conical twin-screw extruder is perfect, with plastic powder or granular material.

2.Mould designed by different kinds of profile customer required.

3.Supply formula guide and staple raw material purchase.

Appliaction of outdoor wall cladding panels

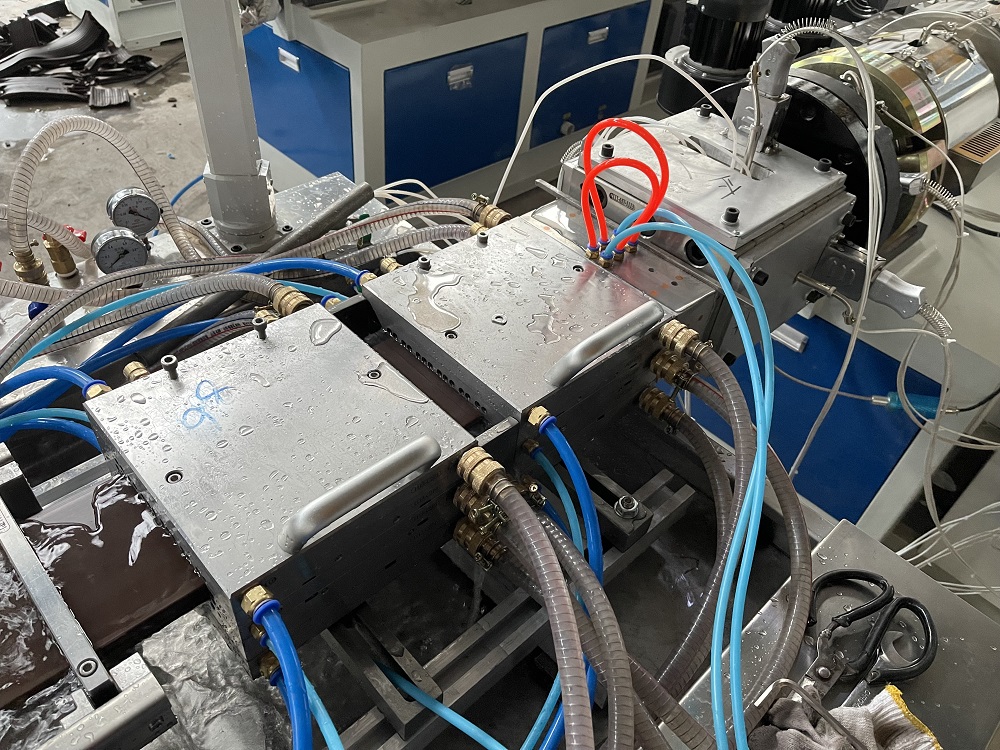

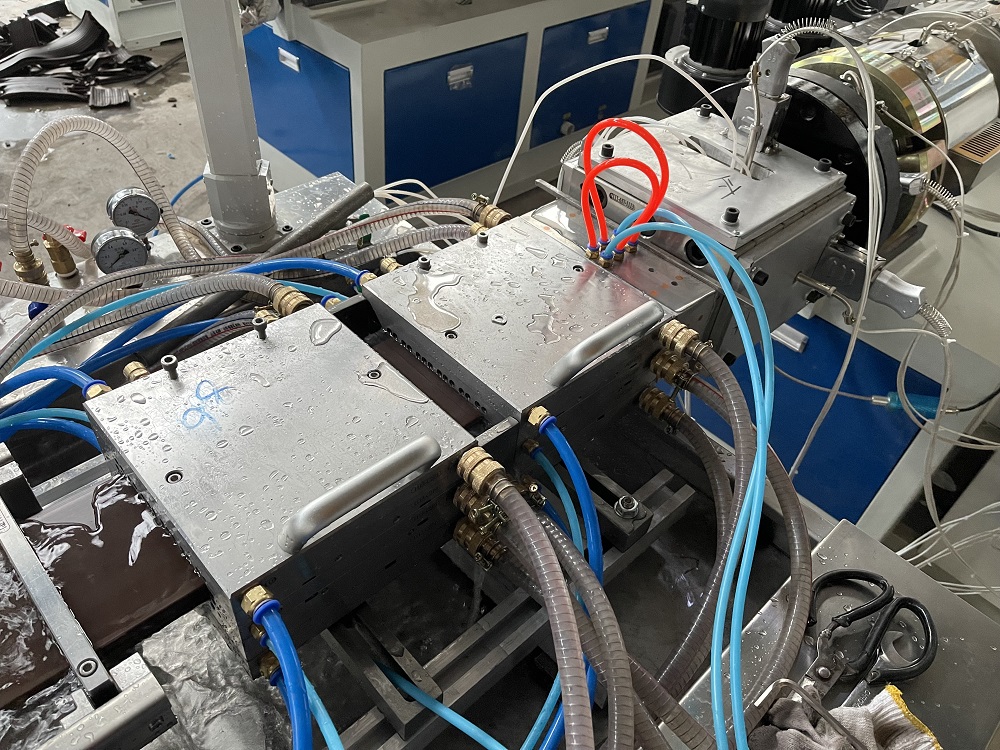

Detail images of WPC Great Wall Panel Machine /outdoor wall cladding panels machine

wpc wall panle production line includes Screw feeder, Double screw extruder, Mould, Vacuum forming table, Haul off unit, Cutter, Stacker.

1.Conical Twin Screw Extruder

Model: SJSZ65/132

Motor power: 37Kw

Screw rotation speed: 1-37rpm/min

Material of Screw and Barrel: 38CrMoAlA,

Nitrogen Treatment Motor brand: Siemens Beide

Inverter: ABB

2.Calibration And Cooling Table

Table length: 4-6meters (Depending on the product)

Forward and backward adjustment Left and right adjustment

Table material in contact with water: stainless steel 304

Water tank can recycle the cooling water

3.Tractor

Traction speed: Adjustable by frequency converter

Clamping method: Manual/Pneumatic

Traction block material: Rubber

4.Cutting machine

Cutting direction: Left to Right / Bottom to Top

Blade material: High quality alloy steel

PLC: Siemens/DELTA

5.Stacker

Discharge Control: Pneumatic drive

Splint material: Stainless steel 304

Length: 4-6 meters

6.Die Head + Forming machine

We can change die head and formaing machine ,then make differnet kinds productions .

Off-line Embossing Machine or online embossing machine

Process Flow

Auxiliary machine

Mixer, Embossing machine, Sanding machine, Brushing machine, Crusher, Pulverizer and so on.