- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

PVC /WPC profile extrusion machine can produce all kinds of profile, for example, window, door and door frame, pallet, cladding of outdoor wall, facility of outside park, floor etc. Output profile is Wood Plastic Composite(WPC) or Plastic UPVC.

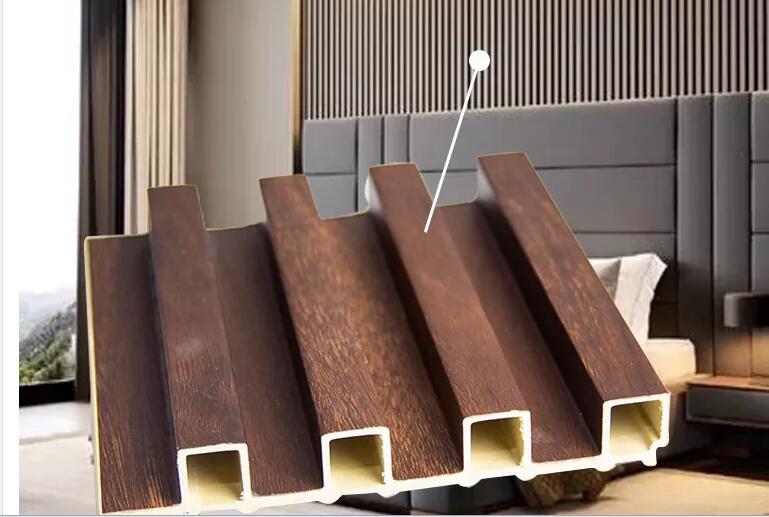

WPC Interior Wall Cladding WPC Great Wall Panels Decorative Wood Plastic Composite Wall Board making machine /production line

Product description:

WPC profile/panel making machine can produce different kinds of profile. Main material is PVC + wood fiber + other chemical additives composite produce. Product included Wall cladding, Wall Panel, Floor, Handrail, Fence, Skirting and fluted panel (Great Wall Plate) etc.

Can also be customized according to customer's drawings and samples

Advantages of WPC (Wood Plastic Composite)

1. Looks and feels like natural wood but less timber problems;

2. 100% recycle, eco-friendly, saving forest resources;

3. Moisture/Water resistant, less rotten, proven under salt water condition;

4. Barefoot friendly, anti-slip, less cracking, less warping;

5. Requires no painting, no glue, low maintenance;

6. Weather resistant, suitable from minus 40 to 60°c;

7. Easy to install and clean, low labor cost.

Technical profile for industry:

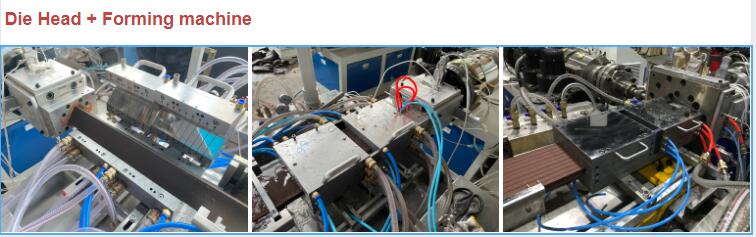

1.Conical twin-screw extruder is perfect, with PVC powder or granular material.

2.Mould designed by different kinds of profile customer required.

3.supply formula guide and staple raw material purchase.

Technical data:

|

Model |

Max width (mm) |

Extruder model |

Max output(kg/h) |

motor power(kw) |

|

CMDX108 |

108 |

SJZ51/105 |

100 |

18.5 |

|

CMDX 180 |

180 |

SJZ51/105 or SJZ55/110 |

100/150 |

18.5/22 |

|

CMDX 240 |

240 |

SJZ65/132 |

250 |

37 |

|

CMDX 300 |

300 |

SJZ65/132 |

250 |

37 |

|

CMDX 400 |

400 |

SJZ80/156 |

350 |

55 |

|

CMDX 500 |

500 |

SJZ80/156 |

350 |

55 |

|

CMDX 600 |

600 |

SJZ80/156 |

400 |

75 |

Application

Detail image

1.Conical Twin Screw Extruder

Model: SJSZ65/132

Motor power: 37Kw

Screw rotation speed: 1-37rpm/min

Material of Screw and Barrel: 38CrMoAlA, Nitrogen Treatment

Motor brand: Siemens Beide

Inverter: ABB

2.Calibration And Cooling Table

Table length: 4-8meters (Depending on the product)

Forward and backward adjustment Left and right adjustment

Table material in contact with water: stainless steel 304

Water tank can recycle the cooling water

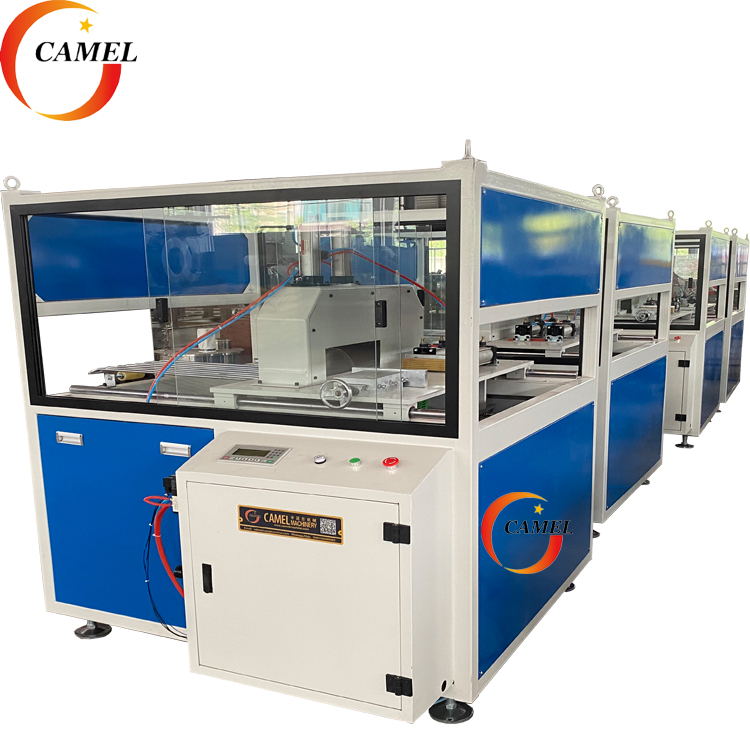

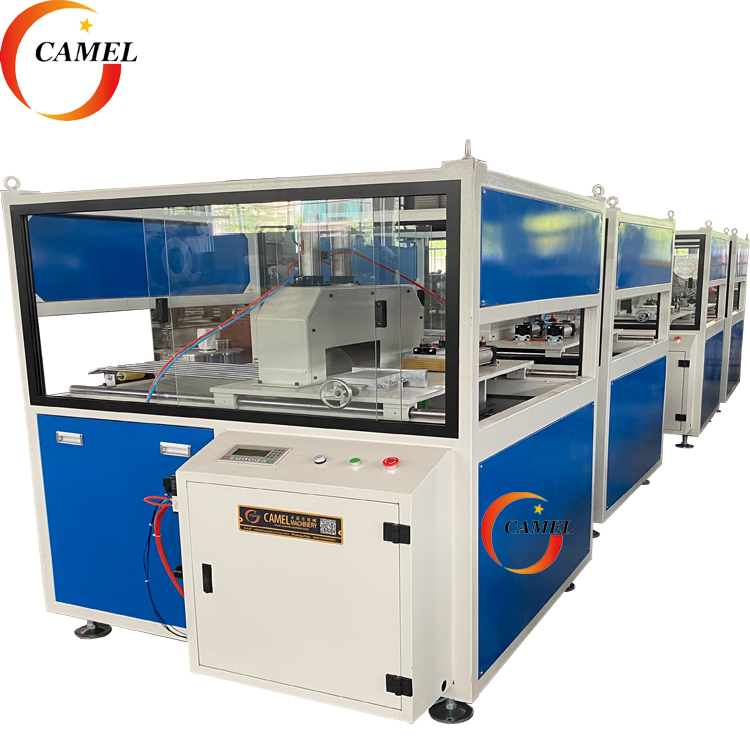

3.Cutting machine

Cutting direction: Left to Right / Bottom to Top

Blade material: High quality alloy steel

PLC: Siemens/DELTA

4.Tractor

Traction speed: Adjustable by frequency converter

Clamping method: Manual/Pneumatic

Traction block material: Rubber

5.Stacker

Discharge Control: Pneumatic drive

Splint material: Stainless steel 304

Length: 4-6 meters

On-line Lamination Machine

Off-line Lamination Machine

Final product