- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

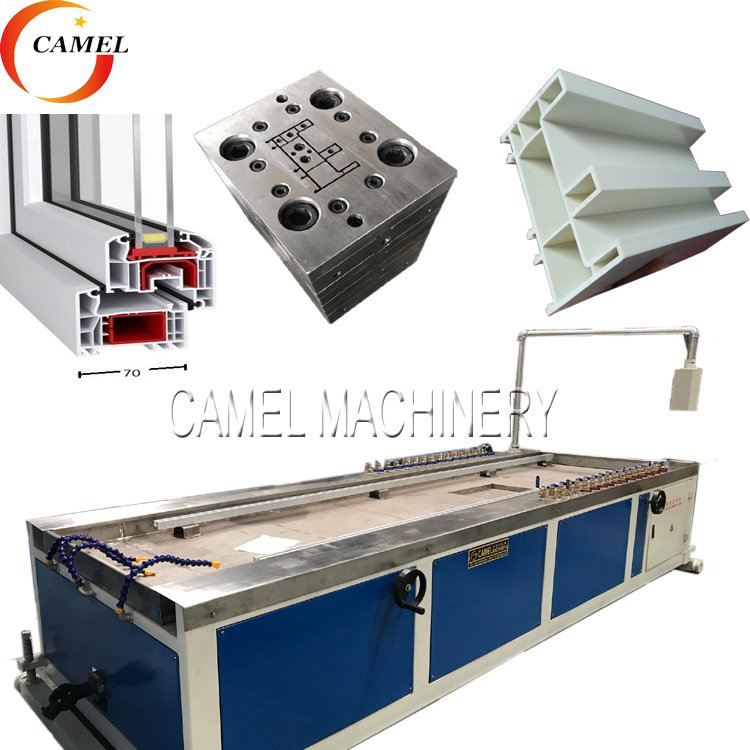

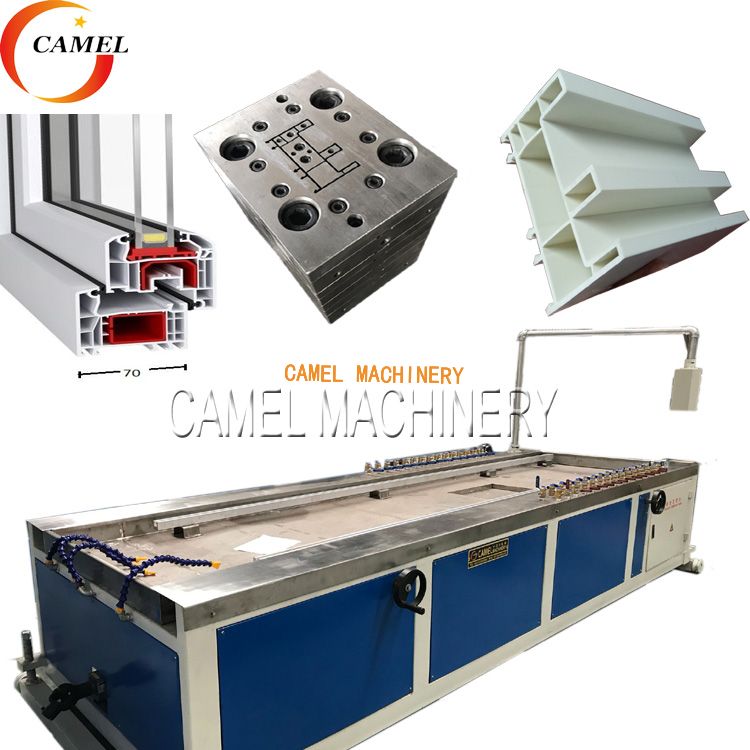

PVC windows line is mainly used for producing various sizes of PVC profiles, pvc cable trunking, ceiling panel, window sill, WPC decking, WPC flooring and other shaped profiles.

PVC Window Profile Production Line /machine /extrusion Line

The pvc windows line is mainly used for producing various sizes of PVC profiles, pvc cable trunking, ceiling panel, window sill, WPC decking, WPC flooring and other shaped profiles.

Normal pvc windows line is composed of extruder, mould, vacuum calibration table, haul-off and cutter, stacker. With different mould, PVC profile machine can produce PVC products with different shapes, Mould designed by different kinds of profile customer required.

Features for pvc windows production line:

* PLC control system is available

* All electrical components adopts famous brand : OMRON, ABB, SIEMENS etc

* Over current protective of motor

* With online protection film wrapping device

Machine Configuration for pvc windows production line:

|

No |

Unit machine |

unit |

|

1 |

Powder Charger (for extruder) |

1set |

|

2 |

Conical Twin Screw Extruder |

1set |

|

3 |

Vacuum calibrating machine |

1set |

|

4 |

Haul off machine together with cutter |

1set |

|

5 |

Stacker |

1set |

|

6 |

Mold (according to the drawing ) |

|

|

7 |

Control cabinet |

Included |

|

8 |

Spare parts |

Free /set |

Auxiliary machines:

1.Mixing unit

2.Crusher and milling machine

3.Chiller and air compressor etc

Process flow:

Raw material +wood power+ additive → mixing → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support → belt haul-off → cutter → rack → finished product inspecting & packing

Technical data:

|

Model |

Max wide(mm) |

Extruder model |

Max output(kg/h) |

Drive motor power(kw) |

|

CMLM108 |

108 |

SJZ51/105 |

100 |

18.5 |

|

CMLM180 |

180 |

SJZ51/105 or SJZ55/110 |

100/150 |

18.5/22 |

|

CMLM240 |

240 |

SJZ65/132 |

250 |

37 |

|

CMLM300 |

300 |

SJZ65/132 |

250 |

37 |

|

CMLM400 |

400 |

SJZ80/156 |

350 |

55 |

|

CMLMC500 |

500 |

SJZ80/156 |

350 |

55 |

|

CMLM600 |

600 |

SJZ80/156 |

400 |

75 |