- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

Winding machines play an important role in the production of plastic pipes. First of all, its packaging form not only greatly saves production space and reduces transportation costs, but also greatly improves the convenience of transportation. This packaging form saves manufacturers a lot of time and energy. Secondly, during the construction process, the coil can be customized in length according to actual needs, which not only reduces the frequency of connection and the risk of leakage, but also greatly improves construction efficiency.

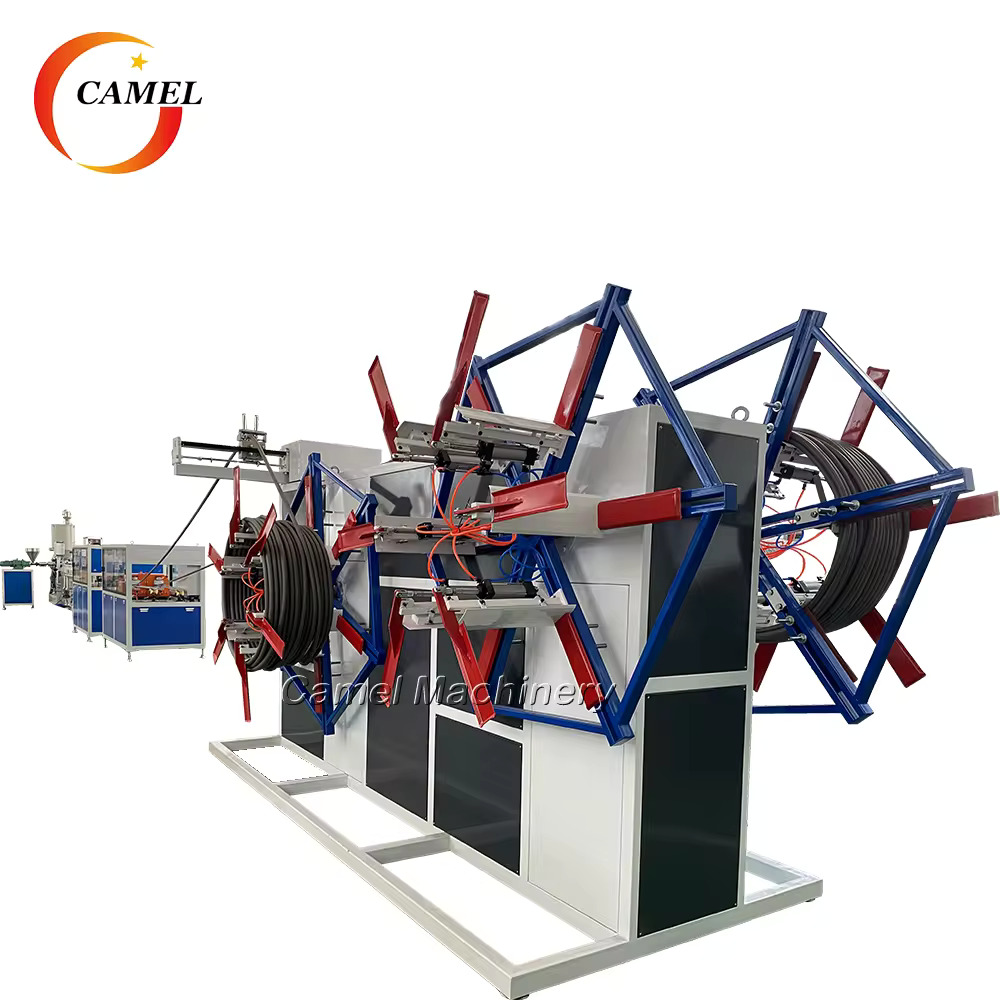

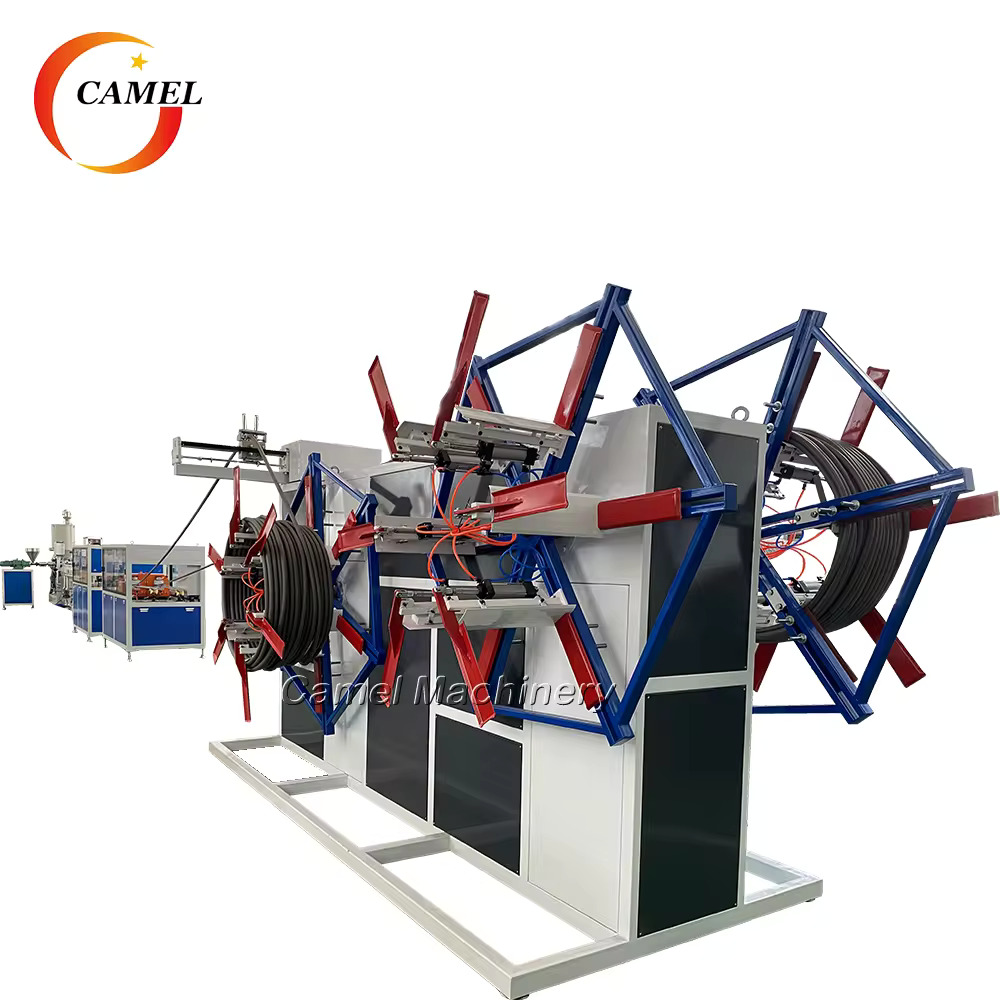

plastic hdpe pp ppr pipe winder machine for sale

Winding machines play an important role in the production of plastic pipes. First of all, its packaging form not only greatly saves production space and reduces transportation costs, but also greatly improves the convenience of transportation. This packaging form saves manufacturers a lot of time and energy. Secondly, during the construction process, the coil can be customized in length according to actual needs, which not only reduces the frequency of connection and the risk of leakage, but also greatly improves construction efficiency.

As a professional manufacturer of plastic pipe production lines in my country, CAMEL is well aware of the importance of winders in the production process. Therefore, it pays attention to every production link and strives to provide customers with high-quality, high-stability and durable plastic pipe production equipment. The company always adheres to the customer-centric approach and strives to meet the actual needs of customers. Whether it is product quality or after-sales service, we strive to do our best.

Final products:

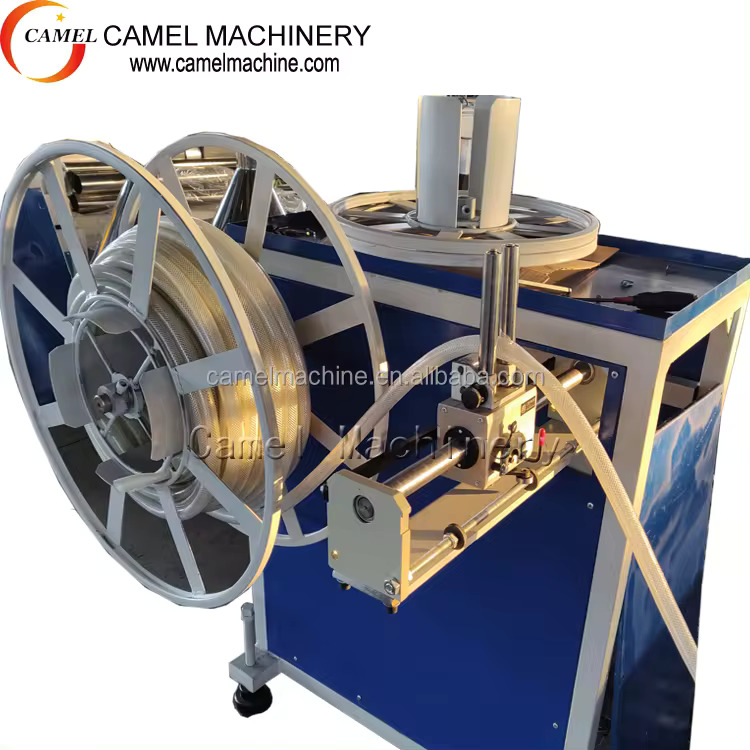

Type 1.--- single disk

Type 1.--- single disk

Type 2.----double disk

Type 3.----Four disk

Type 4.----Semi-auto winder for PVC hose

Application:

The machine was mainly used to tolling and packing of the plastic soft pipings Tt matches other equipment in usage to effect the automatization of processing.

Advantage of plastic pipe winding machine:

1.Fully automatic,save manpower.

2.Suitable for wide range diameter of pipe.

3.Easy to operate,maintain.

4.Lower powder consumption.

Detail technical:

| Model |

Inner diameter of coil |

Outside diameter of coil |

Coil width | Winding speed | Pipe diameter |

Moment motor |

| SPS-32 double stations | 480-800mm | 800-1280 | 200-370 | 1-20m/min | 16-32 | 10N.M |

| SPS-63 double stations | 600-1200mm | 1400-2000 | 360-560 | 1-20m/min | 32-63 | 25N.M |

| SPS-110 double stations | 2500-3500mm | 700 | 0.5-5m/min | 63-110 | 40N.M |