- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

Winding machines play an important role in the production of plastic pipes. First of all, its packaging form not only greatly saves production space and reduces transportation costs, but also greatly improves the convenience of transportation. This packaging form saves manufacturers a lot of time and energy. Secondly, during the construction process, the coil can be customized in length according to actual needs, which not only reduces the frequency of connection and the risk of leakage, but also greatly improves construction efficiency.

plastic hdpe pp ppr pipe winder machine for sale

Winding machines play an important role in the production of plastic pipes. First of all, its packaging form not only greatly saves production space and reduces transportation costs, but also greatly improves the convenience of transportation. This packaging form saves manufacturers a lot of time and energy. Secondly, during the construction process, the coil can be customized in length according to actual needs, which not only reduces the frequency of connection and the risk of leakage, but also greatly improves construction efficiency.

As a professional manufacturer of plastic pipe production lines in my country, CAMEL is well aware of the importance of winders in the production process. Therefore, it pays attention to every production link and strives to provide customers with high-quality, high-stability and durable plastic pipe production equipment. The company always adheres to the customer-centric approach and strives to meet the actual needs of customers. Whether it is product quality or after-sales service, we strive to do our best.

Final products:

Characteristic :

Characteristic :

The servo wiring system allows the pipes to be arranged in order, neatly and beautifully;

The tension adjustment system controls the winding speed, which is synchronized with the production speed

Synchronous adjustment of the reel inner diameter saves more than 90% of the adjustment time when changing specifications

PLC programmable control system, simple operation and convenient adjustment.

high speed pipe winder (Φ63)B series

Characteristic :

The servo wiring system allows the pipes to be arranged in order, neatly and beautifully;

Double-station reeling, quick coil change;

The torque adjustment system controls the winding speed, which is synchronized with the production speed;

PLC programmable control system, simple operation and convenient adjustment;

Optional lifting system can reduce the labor burden.

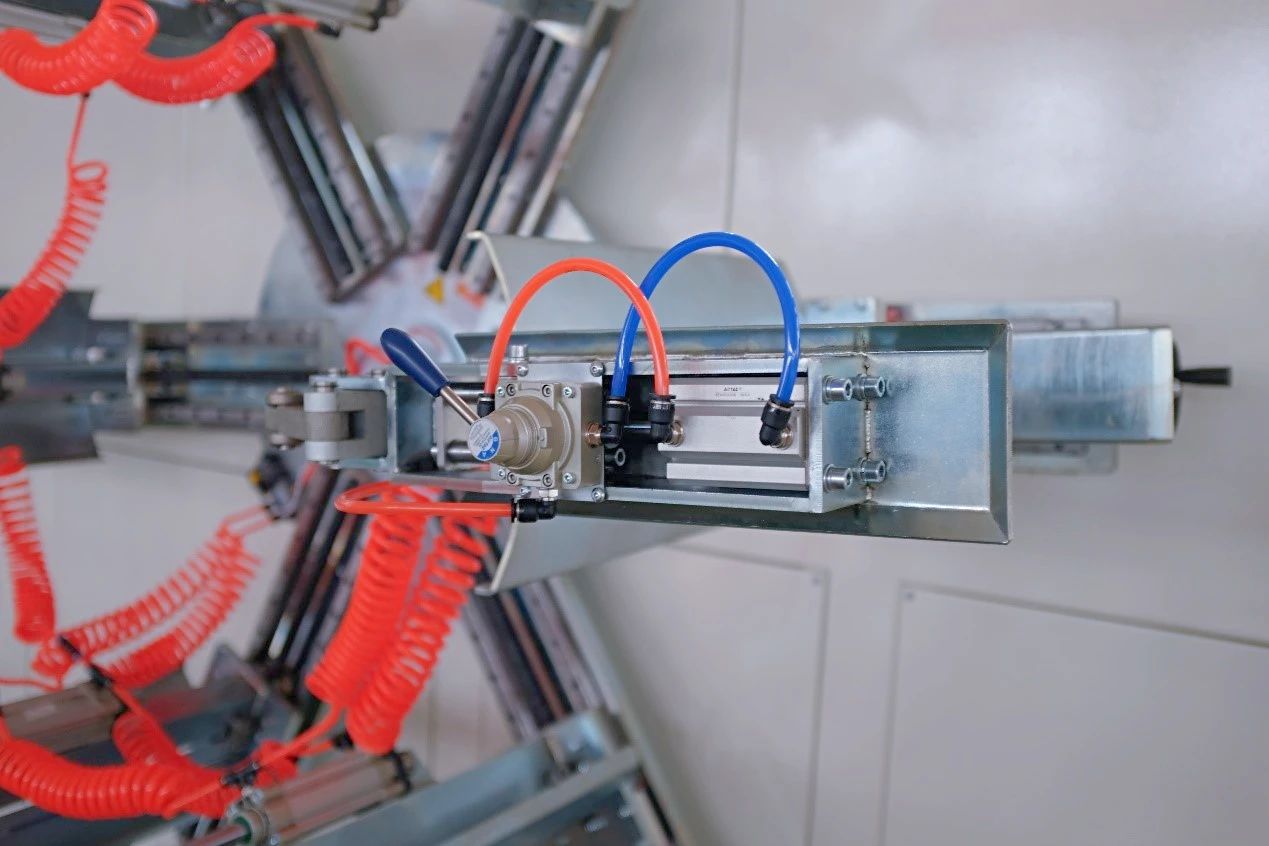

Pneumatic clamping of the starting end of the pipe is safe and convenient

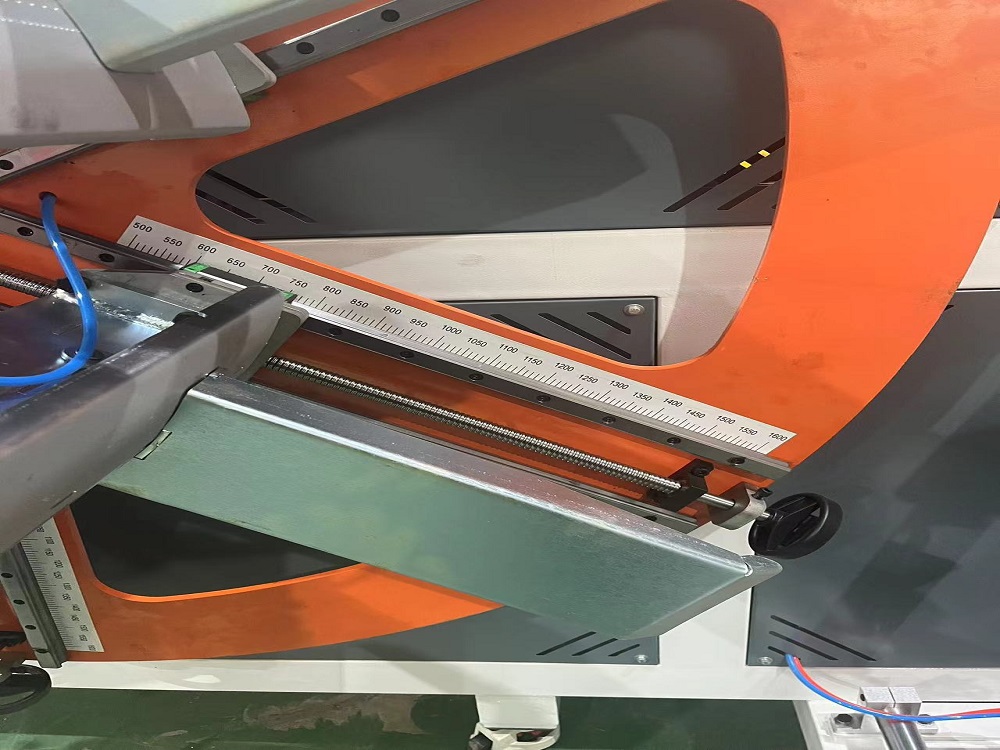

Reel inner diameter adjustment scale display, clear and easy to read

Quick adjustment of the inner diameter mechanism with scale display, the adjustment time is improved by 90% year-on-year

high speed pipe winder (Φ110)C series

Features:

The servo wiring system allows the pipes to be arranged in order, neatly and beautifully;

The torque adjustment system controls the winding speed, which is synchronized with the production speed;

PLC programmable control system, simple operation and convenient adjustment;

Optional hoisting or forklift unloading system to reduce labor burden