- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

Why we produce three-layer pipe instead of single layer:

1. Reduce the production cost. Ususally middle pipe layer will use recycled material, it will reduce your raw material cost, and will not affect the pipe quality.

2. Increase the pipe toughness. Some customer will use glass fiber material in the middle layer, it will be increase the pipe toughness.

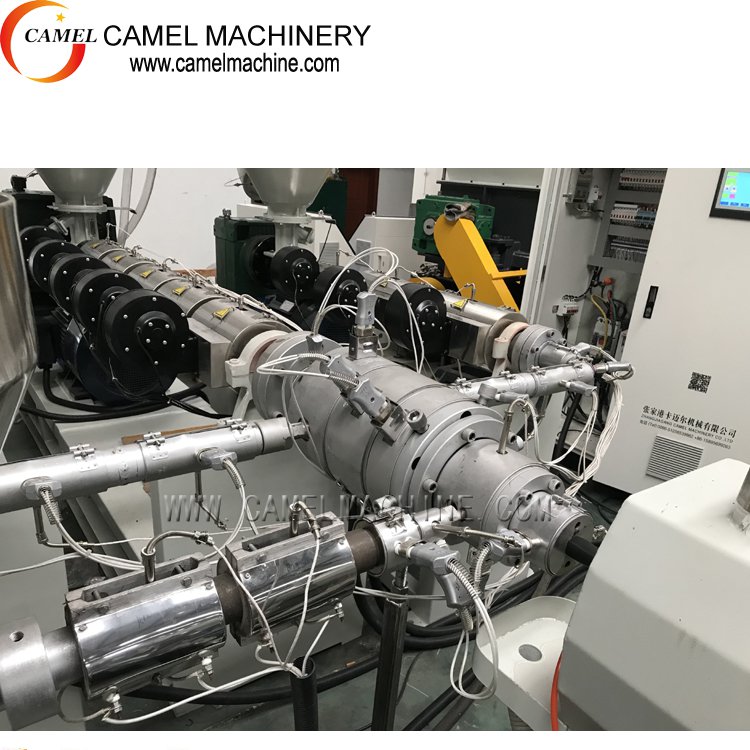

Drive motor: Siemens Beide motor

Inverter: ABB

Temperature control: Omron

Contactor: Siemens

For 20-63mm three layer pipe machine, if you have specific requirement for each layer percentage, we suggest you use three extruder co-extrusion, otherwise 2 sets extruder coextrusion is enough.

Material: 40Cr

Calibrator: Stainless steel

It will be much better if you can tell us the specific pipe size(pipe diameter & pipe thickness or pressure) you want to produce, then we can suggest you the most suitable machine based on your requirements.

Material: Stainless steel

Tank Movement : Forth and back by motor driven Up and down by manual adjust

Material: Stainless steel

Length: 6m or customized

Haul-off Speed Adjustive: ABB inverter

Above Haul-off Bracket Compaction Mode: Adopt pneumatic gas cylinder

Cutting Machine

Cutting Saw: Adopt Alloy Steel Saw

Machine Type: No dust cutting machine

This type cutting machine can reduce the dust in your factory, and with lower norise

Laying Board Material: 1.5mm Stainless Steel Board

Stacking Mode: Stacking by Gas Cylinder, adopt Limited Switch Send out Cutting Signal