- Phone/WeChat/WhatsApp: 0086-15895699263

- Email: sales@camelmachine.com

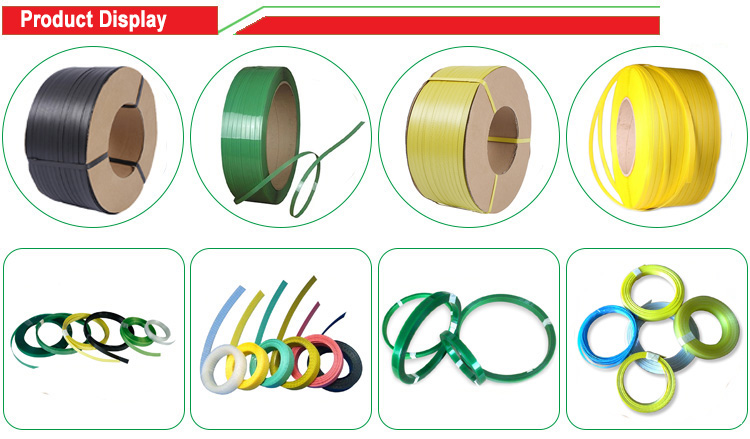

This PP PET strap band/ packing belt production line can produce different width and thickness pp pet strap according to the clients' requirement. The raw material can be 100% recycled material , which can reduce the product cost and get a good profit. The PP belt is the substitution of the steel strap and has a lot of advantages such as good extension, high temperature resistant, easy use. It is mainly suitable for packaging for various trades. The use of the production is convenient and it can adopt common steel fastening for connnection. It also id suitable for various kinds of hand-operated of table packing machine and large quto-packing machines of enterprises.

This PP PET strap band/ packing belt production line can produce different width and thickness pp pet strap according to the clients' requirement. The raw material can be 100% recycled material , which can reduce the product cost and get a good profit. The PP belt is the substitution of the steel strap and has a lot of advantages such as good extension, high temperature resistant, easy use. It is mainly suitable for packaging for various trades. The use of the production is convenient and it can adopt common steel fastening for connnection. It also id suitable for various kinds of hand-operated of table packing machine and large quto-packing machines of enterprises.

Plastic PET/PP packing strap extruder production line Packing belt making machine

Raw material: Waste PE/PET flakes or granule.

Number of strap: 1,2,4,6,

Width: 5mm-22mm,

Thickness: 0.5mm-1.5mm,

Standard: 12×0.8mm, 12×1mm, 13×1mm.

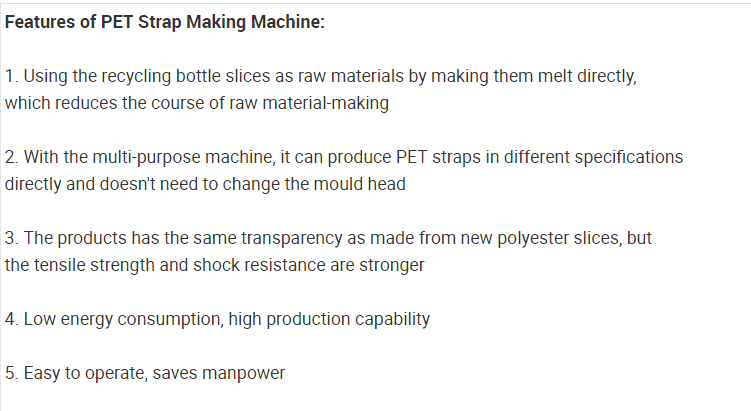

Advantages:

. process 100% recycled PET bottle flakes.

. even plasticization and stable extrusio with PLC automatic control for the whole line.

. as per different requirements, changing a coating materials for making strao has better and special function. For example, the strap for packing cotton can be from enhancing the breaking strength and joint strength when welding strap.

. Melt filter with two pistons with air venting design amd back flushing.

. Production line just need 2-3 workers ,suit to 24 hours moving per day.

. Finished product: width: 5-25 mm, thickness: 0.5-1.5mm.